VINA CABINETRY

|

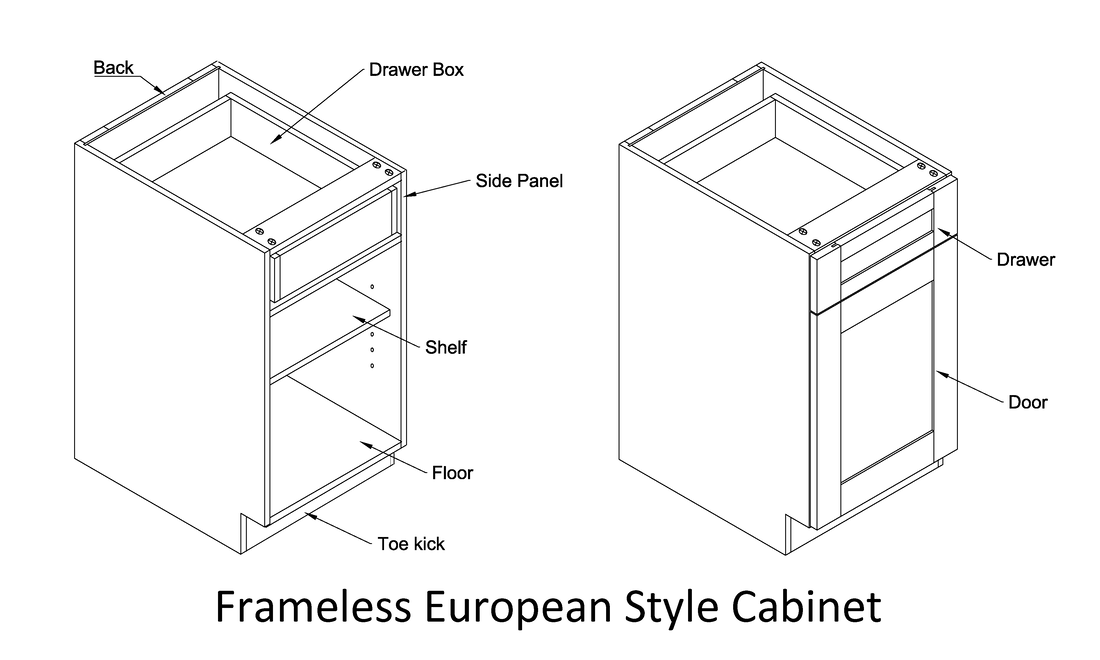

Following World War II, Europe had to face the mass number of houses that had been destroyed. Because solid lumber was not abundantly available, European engineers devised an integrated system of hardware, materials, and machinery to use the particleboard sheets that were available. The result of their innovation has come to be known as the European cabinet system, or 32mm cabinet system.

This new system more than modified former systems. It represented a new direction in philosophy, hardware, fasteners, materials, joinery, and construction techniques. The European system maximized the efficient use of materials, time, equipment, and labor in producing residential and commercial cabinets that were both functional and attractive. As a result of the 32mm system, Europe’s cabinet industry could manufacture thousands of well-built cabinets that met universal specifications. 32mm is a complete "system" of cutting, edge banding, and assembly that is designed to a) produce a large amount of casework quickly and without the need for a lot of skilled craftsmen; and b) create modular cabinetry that can be easily disassembled and moved from one location to another. In most of Europe, cabinets are treated like furniture in that when people move, they take their cabinets with them. Several fundamental differences separate European-style cabinets from traditional American cabinets. The European style cabinet has no face frame and is often referred to as “frame-less.” The box is generally constructed of 5/8"- or 3/4"- thick melamine-coated particleboard. The particleboard’s exposed edges are generally edged-banded with wood or plastic. The toe kick is usually a separate frame, built independent of the cabinet and joined to the cabinet during installation. European-style door hinges are adjustable on three axes, which makes door alignment very simple and quick. The most fundamental difference, and from where the term “32mm system” derives, is the fact that European cabinet design and construction is based on a grid of 5mm holes drilled on 32mm centers. A line boring machine drills these holes, drilling several holes at once and easily indexing for another set to be drilled in perfect alignment. The holes are used for quick and accurate alignment during assembly and when workers attach door hinges, drawer glides, and adjustable shelf pins. Cabinet Sourcing take 32 mm system as a standard through out the production line. Streamlined construction procedures, efficient use of materials, and the look of the finished product have all contributed to the popularization of the European style in the United States. Since World War II, many American cabinet manufacturers have implemented the concepts of the 32mm cabinet system. Cabinet Sourcing use 32mm system and produce both European style cabinet and American style kitchen cabinet. The results of a survey given to exhibitors showed that approximately one fourth of the custom cabinets that the presenters produced were in the European style. The ratio of European-style cabinets to traditional cabinets is likely to be even higher in commercial applications. Apron-front sinks, also known as “farmhouse” sinks, are not a new trend. Far from it, actually. They have been a popular choice among homeowners for several years now, and not even the march of time has been able to slow the proliferation of farmhouse sinks. They can come with a sizable price tag, but more homeowners are showing a willingness to spend more if it means they can have a farmhouse sink incorporated into their kitchen.

Homeowners today are making choices based on aesthetics first and foremost, and when looking for a sink, they are searching for something to anchor their kitchen. It needs to align with their design vision and work in concert with the style of their decor. Understanding the appeal of the farmhouse sink, the styles and materials available to you, and the steps necessary to install one in your kitchen will help you determine if you are one of the many homeowners today who simply can’t live without an apron-front sink. Farmhouse sinks originate as far back as 17th century Ireland and Great Britain. Back then, indoor plumbing and running water were a luxury that not everyone was afforded. Most were forced to fetch waters from nearby wells, meaning every drop of water was important. To hold as much of the water as possible, these people had large sink basins in their homes. Today, there is less concern about conserving every drop of water, but farmhouse sinks are no less coveted. The unique look of the apron-front sink is what tends to draw initial interest. As the name would suggest, apron-front sinks extend forward an inch or two from the countertop. They are generally much deeper and wider than a traditional kitchen sink, giving the homeowner an apron area that is much easier to clean than wood cabinets directly below the countertop. The greater depth of a farmhouse sink allows you to pile up more dishes, more easily clean large pots and pans, and wash and rinse without worrying about a lot of splashing. Perfect for having the kids pitch in to help with dishes! Part of the appeal of farmhouse sinks is the variety of styles and materials from which to choose. White porcelain is a popular choice for an apron-front sink, but there are also homeowners who prefer the superior durability of stainless steel. Although it requires more frequent polishing and maintenance, copper is another choice, often selected for its beautiful color. Polished marble is perfect for adding a touch of luxury to your farmhouse-style kitchen. Fireclay is a lesser known material, but one that has grown in popularity in recent years. It is a mix of enamel and porcelain, fired at a high temperature so that the enamel fuses with the porcelain to create a hard and shiny surface that looks similar to cast iron. Fireclay is a non-porous and durable material, and is an ideal match for a farmhouse-style kitchen. Apron-front sinks are a staple of farmhouse-style kitchens, but they are not limited as a design choice to that one style. You might find a stainless steel apron-front sink in a modern kitchen. More industrial-inspired kitchens could feature a concrete apron-front sink. The functional aspects of farmhouse sinks have also continued to evolve over the last decade. First, there is the choice between a double or single bowl farmhouse sink. You may see crisper and more geometric designs, in addition to built-in drainboards and chopping blocks to appeal to homeowners who desire more modern conveniences. To apply farmhouse sink, you would also need a particular farmhouse sink cabinet. This is a special kitchen sink base cabinet, that is similar to a normal sink base but with a different front. Vina Cabinetry offer high quality farm sink cabinet (FSB30/33/36) to customer's design. Buying bathroom cabinetry or a vanity is a similar process to buying kitchen cabinets. Before you start shopping, make sure you have a well-thought-out plan for your bathroom renovation. You should have a clear vision of what your new bathroom will look like, after exploring various bathroom designs and layouts and planning out space and storage. Finally, you should have a budget to work with.  Cabinet Sourcing Bathroom Cabinet Cabinet Sourcing Bathroom Cabinet Cabinet Drawers Make sure to choose a well-constructed cabinet with drawers at least 3/8-inch to 1/2-inch thick, especially on the bottom. Avoid stapled construction. Ensure drawers are snug in their box, open quietly and glide smoothly. They should not sag when extended fully. Solid wood sides and dovetail joinery marks quality construction practices but substrates, such as plywood, particleboard and medium density fiberboard (MDF) with doweled joinery is a suitable and affordable alternative. Cabinet Materials and Finishes Bathrooms receive considerable wear and tear and it's important to choose materials and finishes that can withstand heat, water and excessive moisture. Typically, cabinetry is constructed of a plywood, particleboard or medium density fiberboard (MDF) box with solid wood door and drawer faces. The number of available material and finish options increase with price point. Manufacturing network of Cabinet Sourcing offer a breadth of painted, stained, glazed, antiqued and distressed finishes and an expansive selection of woods and laminates. Cabinet Doors, Accessories and Hardware Door style and decorative enhancements drive the look of bath cabinetry. Doors may be flush or have an elevated or inset central panel that could be squared, arched or rounded. From craftsman to modern, a number of door styles are available at every price point. An assortment of decorative accessories such as posts, pilasters and wainscoting further customize the look. Drawers and doors typically look best when coordinated or identical. The same applies to their hardware, including hinges, knobs and pulls. It's important to thoroughly consider each of these items as an entity before committing. But bath cabinetry isn't all about looks. Consider accessories for ease of use. Mid and high-end cabinetry offer an abundance of features, such as pull-out hair dryer drawers with electrical outlets installed inside doors and wire clothing hamper drawers. Cabinet and Vanity Styles Consider first what you'll be storing in cabinetry before deciding on a design. A double sink vanity offers more storage while a narrower vanity allows more floor space. Another trend is custom designed vanities suspended above the floor. Wall-hung vanities show more floor beneath, lending bathrooms a larger sense of space. Freestanding vanities and cabinetry detached from walls on either side are especially popular in powder rooms or half baths. Cabinets sold specifically as bathroom cabinets are generally 32 inches tall and 18 to 21 inches deep. However, kitchen cabinetry suits bathroom applications, differing only slightly in height and depth. Our Vietnam kitchen cabinet factory is up and running, and already export containers to US. Lead time 60 days. Our mission is to supply high quality cabinetry with reasonable price. Welcome to contact us for quote or more information.

www.cabinetsourcing.com copy right reserved.

Due to trade war between US and China, and the AD/CVD investigation towards imported kitchen cabinets and vanities from China, we received many enquiry about the possibility buying from a outside China source. While it is closing to the preliminary decision of DOC for AD/CVD rate, it become extremely urgent for kitchen cabinet and vanity distributors in United States to find the legitimate, secure substitute of cabinetry supply outside China. When looking for a solution, be careful as what you are encountered maybe trap instead of opportunity. Find out if they are actually produced outside China. When a company claim they are a Vietnam kitchen cabinet factory, find out if they do own any production facility in Vietnam. As many company still produce their kitchen cabinets in China, and then ship the containers to Vietnam. This operation may become target of US custom who is closely monitoring South East countries like Vietnam. Therefore, buying cabinets this way could be risky. Tips: Go and visit the factory in Vietnam personally before you place an order. Status of the Cabinet Factory. It is true that there are some Chinese cabinet manufacturers that already make efforts to build new factory in Vietnam or Malaysia or other country now. With different source and ability, their progress could be faster or slower, and in most cases, much slower than expected. Tips: Estimate the time your inventory could last and prepare a plan B. As a cabinet manufacturer in Vietnam tell you they are putting into production soon, it could be months, or even longer before they can actually begin producing any kitchen cabinets, let alone if their production capacity could meet your needs. Price issue. Due to lower working efficiency and expensive material and other factors, It is inevitable that price of a Vietnam factory or Malaysia factory will be higher than China. The key is to find a reasonable price if your Vietnam supplier can guarantee the quality and lead time. When China stop to supply cabinets, other countries can never fill the supply ability gap that China leave. Some Chinese cabinet factory would move or build their production capacity in South East Asia, but we figure these factory will account for no more than 30-40% of all Chinese cabinet companies. There will be huge supply gap. The result is US cabinet company will need to fight for limited production capacity and some will close their business if they fail to secure their supply. You have not seen this happen, why? It is not easy for kitchen cabinet company to change their supplier and most of them are still watching before August when preliminary decision of AD & CVD come out. But it would be too late for you to make decision and act at that time. The whole industry of cabinetry are facing major and permanent change. Every one is forced to make some major decision and change in order to survive. Take action quickly, but carefully. Simple rules of kitchen cabinet layout

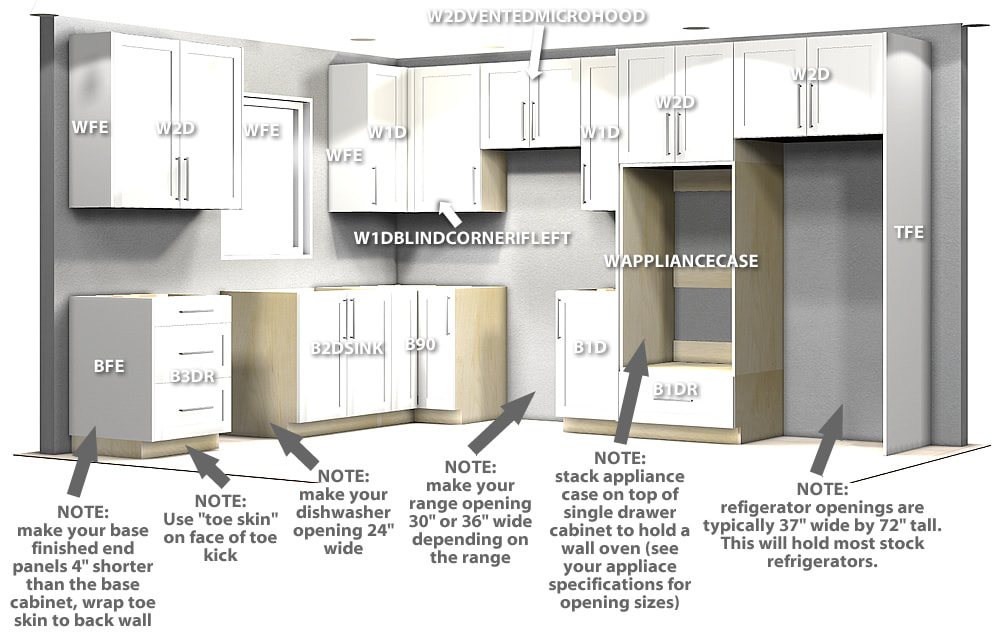

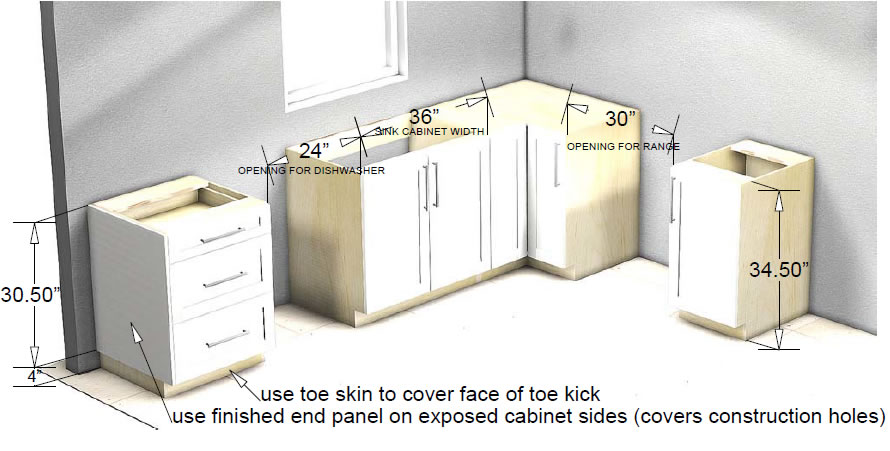

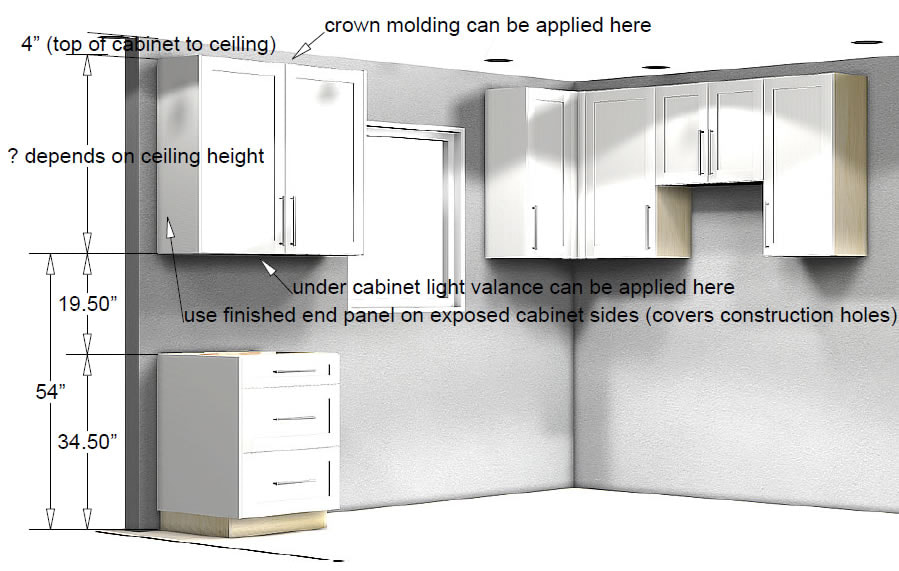

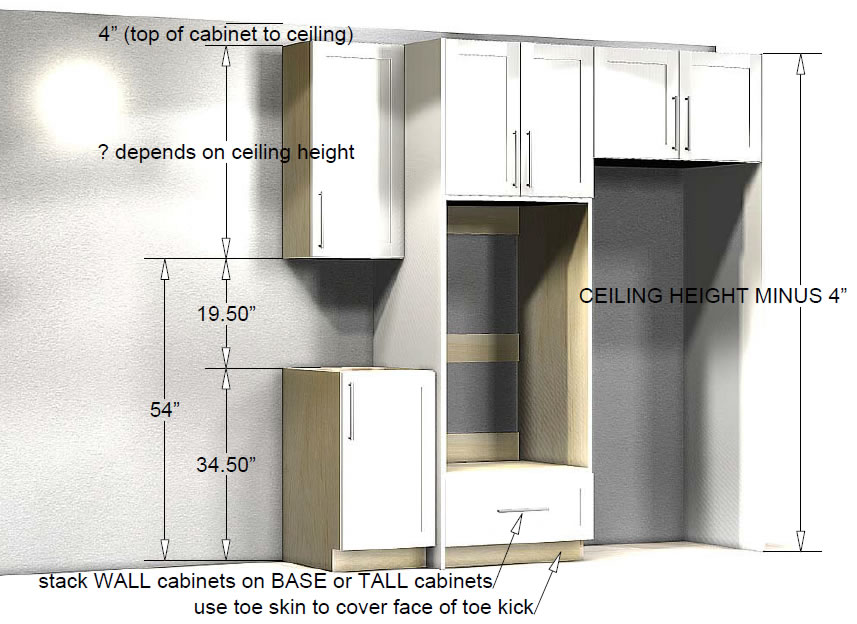

1. Finished ends should be applied to the end of the kitchen cabinet run when visible. Finished ends are used to cover screw holes and screw heads on the exposed sides of the cabinets. 2. Use fillers between the kitchen cabinet run and the wall. A minimum 2" wide filler will take care of walls being out of square and ensure that doors and drawers can open without rubbing on the wall. 3. Toe skins and crown molding finish out the kitchen cabinet project. Toe skins cover the face of toe kick area on a cabinet run and make it look like a single cabinet unit was built. Crown molding and other optional mill-work pieces can be used to add detail to the project. 4. Use PRO. Cabinet Sourcing has more than 10 years experience in kitchen cabinet manufacturing and is able to produce any size and cabinet unit that cater to any layout and help accomplish a great kitchen cabinet project. Recognize the differences between cabinet construction types, materials and quality will help you understand the wide price variance in the kitchen cabinet market.

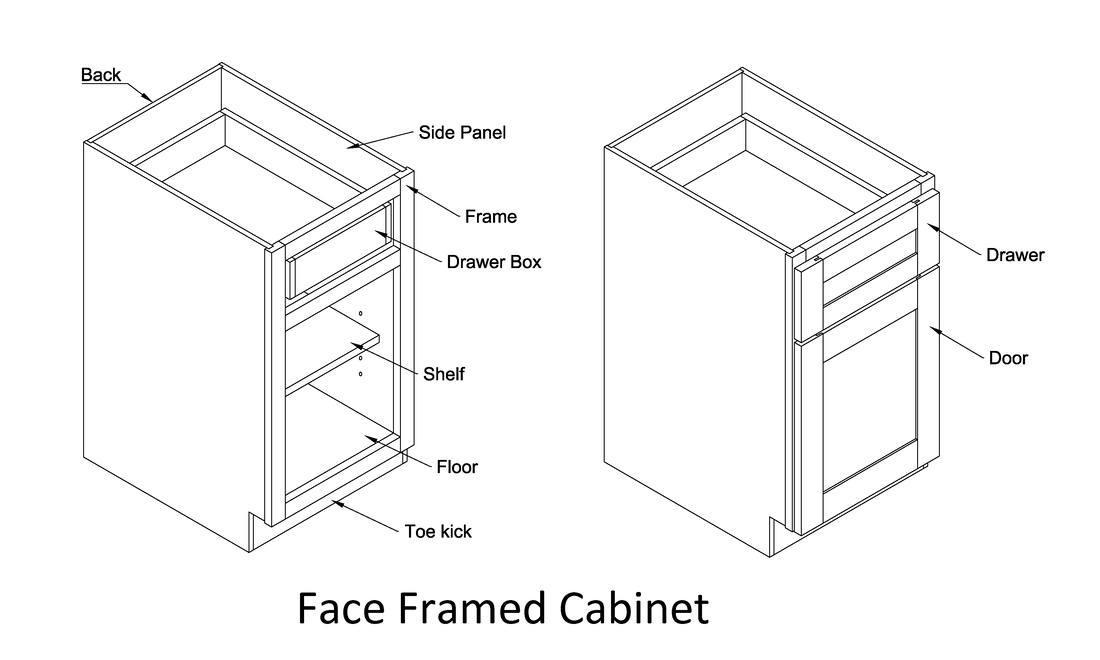

There are two main types of cabinet construction offered to US consumers: framed and frameless (Euro style). Each has structural and stylistic advantages and disadvantages. When comparing framed vs frameless construction, the most important considerations are box construction, materials used, quality of the finish and drawer box construction and assembly. These are the areas where cabinets first show wear and tear, including damage during installation. Framed Cabinet Construction is really a box with six sides: front, back, left side, right side, top and bottom. The cabinet front includes a wood face frame and doors and drawer fronts. The face frame is attached to the cabinet box. Hinged to the face frame, cabinet doors are either inset flush with the frame or overlay the frame. US consumers traditionally prefer framed cabinetry. There are three variations of framed cabinetry: partial overlay, full overlay and inset. Inset styles reveal the entire face frame. Full overlay styles cover nearly the entire frame, while partial overlay styles reveal the frame with large gaps between doors and drawer fronts. Cabinet Sourcing supply all framed construction in either full-overlay or inset to US cabinetry distributors. Frameless (Euro) cabinet, also known as a European-style cabinet, has no face frame. Therefore, the cabinet is a five-sided box. The door, hinged directly to the cabinet box, forms the entire cabinet front. Frameless construction requires thicker side panels to provide stability and a base for hinges. This adds weight to the cabinet. Cabinet Sourcing has rich experience in helping customers who need frameless European style cabinets. Many frameless cabinet boxes are built of particleboard as an more cost friendly option for builder or large apartment projects. Ready-to-Assemble (RTA) Cabinets can be framed or frameless. The unassembled cabinet typically broken down into multiple parts (cabinet, face frame, drawers, inserts, doors and hardware). RTA kitchen cabinets are designed to be assembled on site by DIY home owner or in warehouse of a cabinet distributor. Cabinet parts are joined with a cam lock or screw and metal bracket or just with glue and staple. RTA assembly requires skill to ensure the cabinets are safely assembled and square. Once RTA cabinetry has been assembled, cabinets should be moved as little as possible before installing to prevent structural damage. Kitchen Cabinet refacing is not a cabinet construction method, but a process. Refacing involves removing doors, drawer fronts and hardware. The existing cabinet boxes are then, still installed, covered with veneer panels, paint, or stain. New doors and drawer fronts are then installed on the cabinets. The kitchen layout (footprint) and cabinet interiors, including drawer boxes will remain the same.  High Quality RTA kitchen cabinets by Cabinet Sourcing High Quality RTA kitchen cabinets by Cabinet Sourcing RTA kitchen cabinets are currently dominating the market with the great value. Still, as with any product, there are a number of factors you should consider before making a purchase. The name RTA gives people the impression that all they have to do is remove the parts from the box and place them on spots. Unfortunately, this isn’t the case. Of course, you don’t need the multitude of tools a custom kitchen cabinet would require, but you still need the basic instruments to assemble the RTA kitchen cabinet. The first things you will need are a screw driver and drill, two basic tools required in any home improvement job. Additionally, you’ll want to have a leveler handy to ensure that your kitchen cabinets aren’t slanted towards one side. The last two tools you’ll need are less common in many households. Firstly, you need a table saw to cut your fillers and moldings. A table saw will guarantee smooth, accurate cuts and save you quite a bit of time. Secondly, you need a nail gun to install all your wooden parts. Having a powerful nail gun will allow you to install your panels, fillers, and moldings correctly and in good time. If you have knowledge and practice in renovations, you’ll become quite comfortable with kitchen cabinet installation in no time. The initial assembly will be quite easy, and after you get through your first few kitchen cabinets, the rest will be a breeze. However, it would be prudent to warn those who have no experience in DIY that the cabinet installation isn’t as straightforward as you might’ve initially thought. It can be quite challenging if you aren’t familiar with the tools and techniques. If this is the case, it’s recommended that you hire a professional to finish the job. Considering how much you’ve saved from purchasing the RTA kitchen cabinet, a quick installation from an expert won’t be too imposing on your wallet. When purchasing RTA kitchen cabinet, you should make sure that what you’ve paid for is what you’ll get. Imagine receiving your order, only to be forced to send the entire thing back because you simply aren’t satisfied. This disappointment might occur because of your specific monitor settings or quality, or even due to the fact that the retailer has edited its images. Regardless of why the actual cabinet might look different in person, you should be heedful of the possibilities. In order to ensure that you’ll be pleased with your choice, order a sample kitchen cabinet door first. When you can’t be sure of how the cabinets will look like through an online gallery, a sample will give you a clear idea of what the RTA kitchen cabinets will look like in your kitchen. Another huge advantage of ordering sample doors is that you can ask for multiple different ones, giving you the opportunity to compare each option before you decide on the best fit. While RTA kitchen cabinets are high-quality products, you can’t expect the same level of aesthetics as you might get from custom cabinets. You might wonder why cheaper Ikea products have better finishes than your kitchen cabinets, but you have to take into account that they’re mainly constructed with particle boards and veneers. This means that Ikea can create a clean finish on the outside, but it’s done in order to conceal the cheaper interior build. Cabinet Sourcing, as the leading cabinet manufacturer in China, instead, insist on using best material to produce all solid wood RTA kitchen cabinets with superior interior build. Most of the RTA kitchen cabinets are made of solid wood, and natural materials like this always contain some flaws. Little scratches or warping in between or behind the cabinets are completely normal, but won’t adversely affect the functionality or overall aesthetics of the product. You can always exchange certain parts and request replacements from your retailer, but keep in mind that you won’t receive any reimbursements for them, and doing so will only extend the installation process. Online RTA kitchen cabinets and bahtroom vanities are meant to give you an affordable alternative, and therefore, you can’t expect the same level of service or elegance as you might find in custom cabinet stores.  Wall Cabinet by Cabinet Sourcing Wall Cabinet by Cabinet Sourcing Wall cabinets are 12" deep, but unlike base cabinets, they vary in height. The most common height is 30", but 24", 18", 15" and 12" heights are available (Cabinet Sourcing have a 21" height and 18", 24" and more heights according to customer needs). They range from 9" wide to 48" wide in 3" increments. The 30" height cabinet usually has all 3" increments available. If any are missing from the “lineup” it’s likely to be the 45" and/or 39". The other heights have fewer width choices. Wall cabinets through 24" wide are single door. Though some 24" cabinets are available in double door. Some manufacturers have reversible doors while with others you have to specify “hinged right”, or “left”. Though certain styles of any door may not be reversible, such as a cathedral style (reversing the doors often means just turning the wall cabinet upside down). Wall cabinets usually have four numbers plus one or more letters in their name. The numbers list the width first, then the height, in inches. Some common letter names include: “W” for wall, “DW” for diagonal wall, “WC” for wall corner and more. Some manufacturers add a letter or change them around as there is no standard. For example, “WDC” might mean wall diagonal corner. Some put the letter first and the number second, others reverse the order. Become familiar with your suppliers “code”. 24" deep wall cabinets are for a “top” over utility and/or oven cabinets of the same width. Some "tall" cabinets are 66" (5'-6") tall, with this 18" height cabinet on top they equal 84" total height. PENINSULA OR DOUBLE FACED WALL CABINETS Wall cabinets that go over a peninsula or island usually have doors that open from both sides. The dining room side may have decorative glass in the doors. These cabinets are often shorter so a better view into the other room is possible. The 24" height is common, with 30" also available.In some peninsula layouts doors opening from both sides may not be wanted. Regular wall cabinets can be used with prefinished 1/4" plywood used as a back. This is available stained to match, usually with or without V-grooves. CORNERS WITH WALL CABINETS Turning corners in wall cabinets is not as difficult as with base units. The drawer clashing problem is not present. Still, if you get two doors in a corner with their hinges back to back, it’s possible they will clash and the doors will only open part way. It depends on door thickness, etc. But be aware of it. Many of the same type cabinets help turn wall corners as did the base units. Since peninsula cabinets were just discussed, that is what starts off this section. OTHER... Many other accessories and some other cabinets may be available from different manufacturers. A common one is the microwave cabinet. More accessories include: wall fillers, end panels, plate rails, various mouldings, what-not shelves, valances, wine racks, spice racks and more. EXTENDED STYLES Some manufacturers of “made-to-order” cabinets allow you to order an “extended style” (meaning vertical millwork piece) for an extra charge. This allows flexibility to cut to size on the job for that final fit. This is especially good with remodelling when walls are not plumb and/or the finish wall is not in place when you have to measure and order cabinets. The extra amount can be scribed or trimmed for exact fit.  Dovetail face framed kitchen cabinets Dovetail face framed kitchen cabinets Sliding dovetails provide several advantages over a dado joint. First, they're stronger because they don't rely solely on glue. Second, the shoulders of the dovetailed piece hide the edges of the slot, much as a tenoned workpiece hides a mortise. And the exposed dovetail provides a visible signature of your craftsmanship. Cabinet Sourcing is proud to make high quality sliding dovetail face framed kitchen cabinets. Also we can make similar construction where top and bottom connect to sides. This construction save our customers assembly time and make it easier. To make this joint, you'll rout the dovetail slot first, then cut and size the dovetail to fit. For the slot you'll need a handheld router and the dado jig shown below. In addition to a 5⁄8 " guide bushing, you'll need a 1⁄4 " spiral downcut bit for clean cuts (a 1⁄4 " straight bit will also work) and a 1⁄2 " dovetail bit. We chose a 7° dovetail bit because it leaves a thicker, stronger "neck" on the dovetail than a 14° bit would. You will shape the dovetail on a router table. For testing the router-table setup, prepare a panel the same thickness and about the same width as the project panels to be dovetailed. You will cut the dovetail slot in two operations. First, to reduce the load on the dovetail bit, remove most of the waste with the spiral downcut bit. Then switch to the dovetail bit to complete shaping the slot. Because the dovetail slot tapers from bottom to top, the inside edges of the jig do not align with the top edges of the slot, photo below. To reposition the jig accurately for each operation, use the jig to draw layout lines on your workpieces to define both sides of the slots. Install the bushing and spiral downcut bit, and set the bit's cutting depth to 1⁄16 " less than the final depth of the slot. Clamp the jig along the layout lines and rout across the panel. Rout each slot with this setup. |

Archives

May 2024

Categories |

RSS Feed

RSS Feed