VINA CABINETRY

|

Simple rules of kitchen cabinet layout

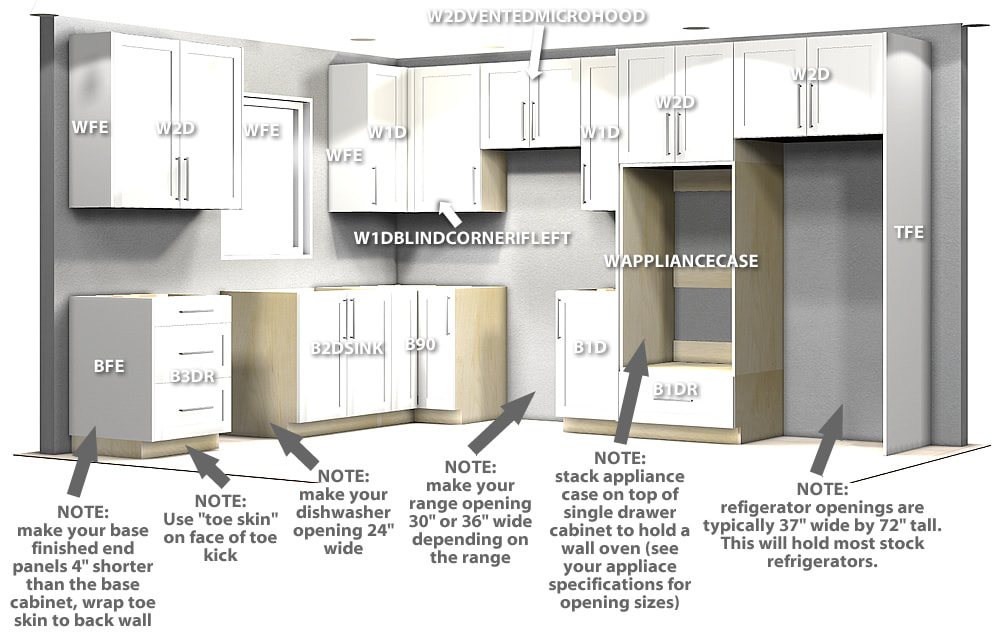

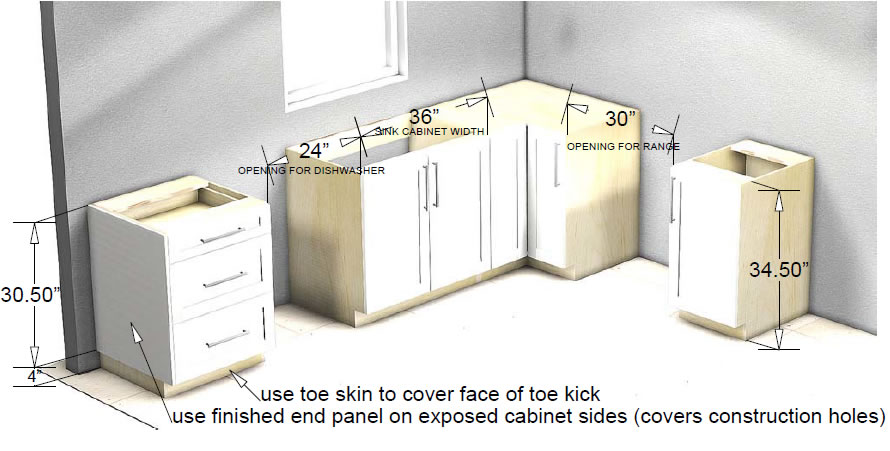

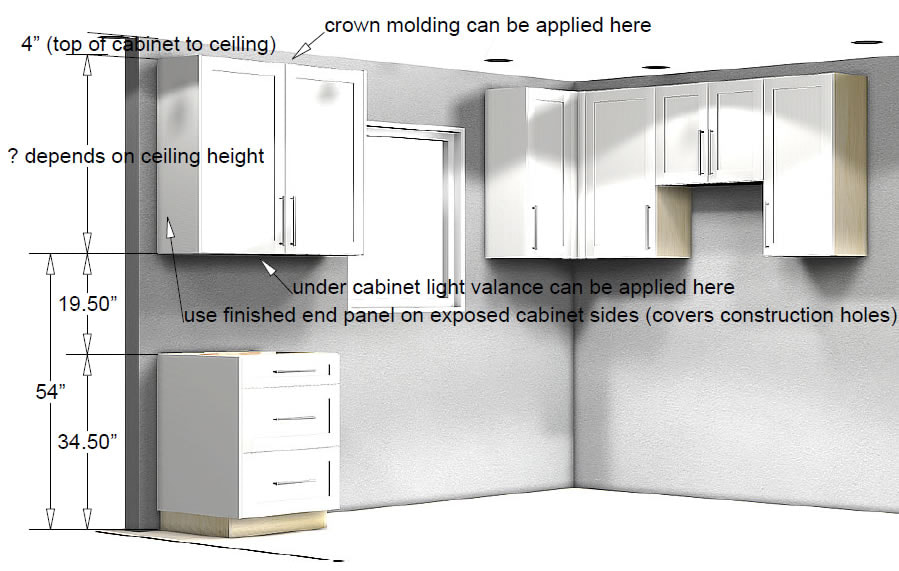

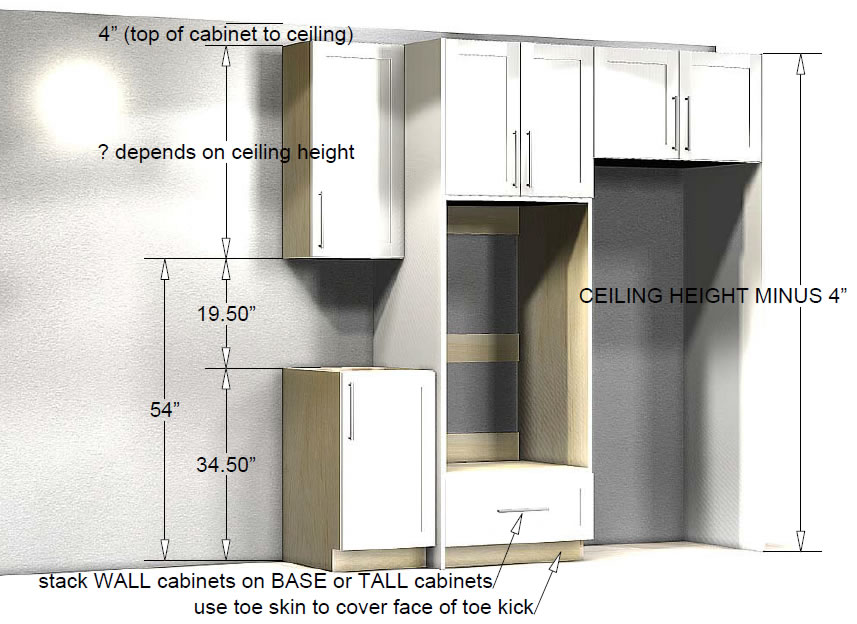

1. Finished ends should be applied to the end of the kitchen cabinet run when visible. Finished ends are used to cover screw holes and screw heads on the exposed sides of the cabinets. 2. Use fillers between the kitchen cabinet run and the wall. A minimum 2" wide filler will take care of walls being out of square and ensure that doors and drawers can open without rubbing on the wall. 3. Toe skins and crown molding finish out the kitchen cabinet project. Toe skins cover the face of toe kick area on a cabinet run and make it look like a single cabinet unit was built. Crown molding and other optional mill-work pieces can be used to add detail to the project. 4. Use PRO. Cabinet Sourcing has more than 10 years experience in kitchen cabinet manufacturing and is able to produce any size and cabinet unit that cater to any layout and help accomplish a great kitchen cabinet project. Recognize the differences between cabinet construction types, materials and quality will help you understand the wide price variance in the kitchen cabinet market.

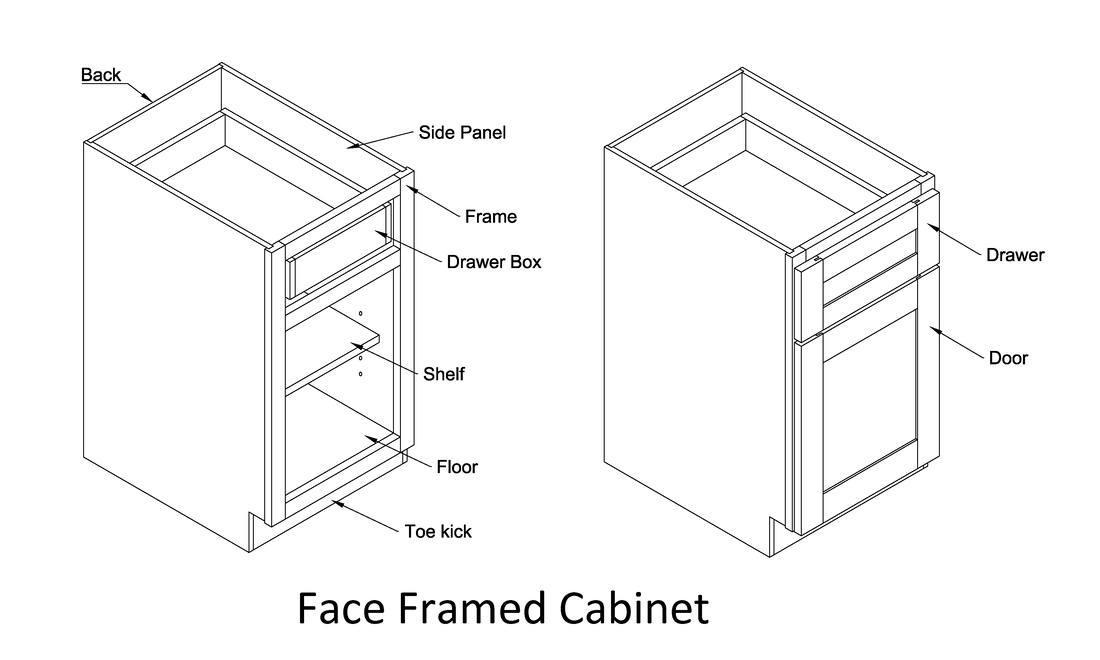

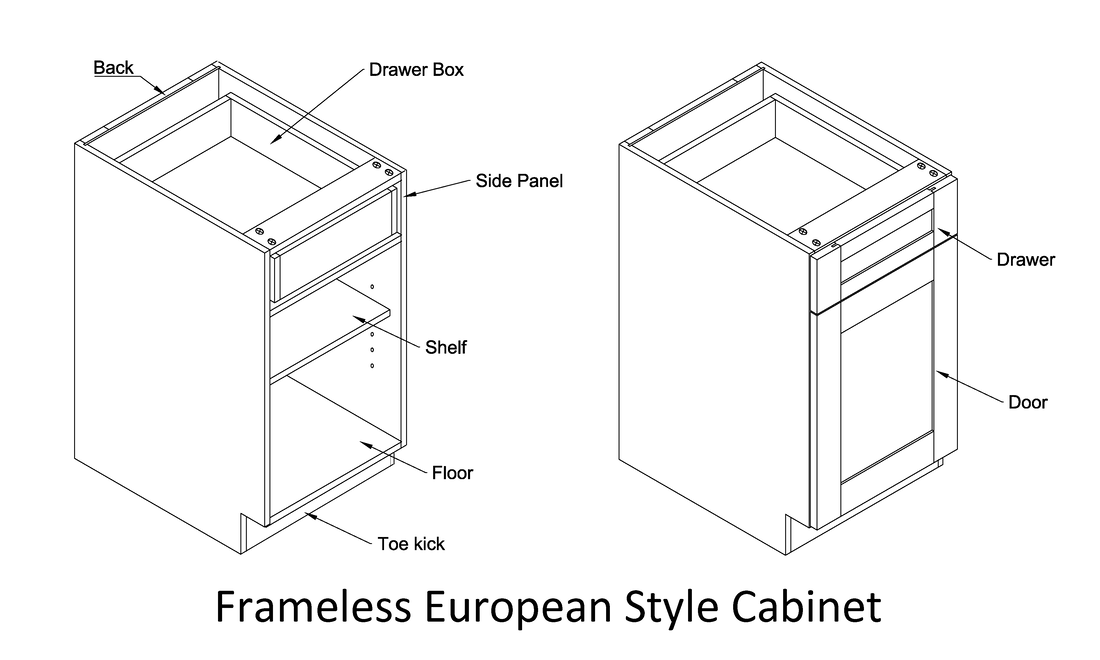

There are two main types of cabinet construction offered to US consumers: framed and frameless (Euro style). Each has structural and stylistic advantages and disadvantages. When comparing framed vs frameless construction, the most important considerations are box construction, materials used, quality of the finish and drawer box construction and assembly. These are the areas where cabinets first show wear and tear, including damage during installation. Framed Cabinet Construction is really a box with six sides: front, back, left side, right side, top and bottom. The cabinet front includes a wood face frame and doors and drawer fronts. The face frame is attached to the cabinet box. Hinged to the face frame, cabinet doors are either inset flush with the frame or overlay the frame. US consumers traditionally prefer framed cabinetry. There are three variations of framed cabinetry: partial overlay, full overlay and inset. Inset styles reveal the entire face frame. Full overlay styles cover nearly the entire frame, while partial overlay styles reveal the frame with large gaps between doors and drawer fronts. Cabinet Sourcing supply all framed construction in either full-overlay or inset to US cabinetry distributors. Frameless (Euro) cabinet, also known as a European-style cabinet, has no face frame. Therefore, the cabinet is a five-sided box. The door, hinged directly to the cabinet box, forms the entire cabinet front. Frameless construction requires thicker side panels to provide stability and a base for hinges. This adds weight to the cabinet. Cabinet Sourcing has rich experience in helping customers who need frameless European style cabinets. Many frameless cabinet boxes are built of particleboard as an more cost friendly option for builder or large apartment projects. Ready-to-Assemble (RTA) Cabinets can be framed or frameless. The unassembled cabinet typically broken down into multiple parts (cabinet, face frame, drawers, inserts, doors and hardware). RTA kitchen cabinets are designed to be assembled on site by DIY home owner or in warehouse of a cabinet distributor. Cabinet parts are joined with a cam lock or screw and metal bracket or just with glue and staple. RTA assembly requires skill to ensure the cabinets are safely assembled and square. Once RTA cabinetry has been assembled, cabinets should be moved as little as possible before installing to prevent structural damage. Kitchen Cabinet refacing is not a cabinet construction method, but a process. Refacing involves removing doors, drawer fronts and hardware. The existing cabinet boxes are then, still installed, covered with veneer panels, paint, or stain. New doors and drawer fronts are then installed on the cabinets. The kitchen layout (footprint) and cabinet interiors, including drawer boxes will remain the same. |

Archives

May 2024

Categories |

RSS Feed

RSS Feed