VINA CABINETRY

|

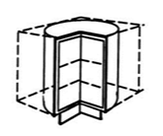

Two corner cabinets that cut down on problems in turning corners are the “lazy susan” base and the “blind corner” base.

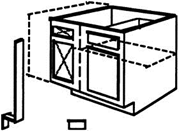

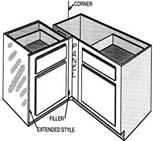

LAZY SUSAN BASE 36" wide Always takes up 36" of wall space. Makes good use of corner space but does not allow any adjusting for odd dimensions in a run of base cabinets. BLIND CORNER BASE 36" to 51"wide Manufacturers make enough sizes to cover every distance from 36" of wall space to 51". They do this by making the style (panel) between the door and the opening wide enough so the cabinet can be slid forward (called “pulled”) up to 3" and for some models up to 7". Notice on the illustration that the cabinet box is usually made short so it doesn't go back to the wall. Often it is up to 12" away from the back wall. This cuts down on storage space a little. This cabinet gives a lot of flexibility when a run of cabinets has to fit exactly between two fixed points. When designing be sure to put it into the correct run of cabinets, if you have a choice (the run that has the fixed points). TURNING CORNERS A concern of anybody who plans kitchen cabinet layouts is to get the corners correct. The problem is shown in the adjacent figure. Drawers may be restricted from opening by the next drawer at right angles, or if it clears the drawer, it may clash with the drawer pull or knob. Many cabinets have no knobs or pulls, so the drawer may clear fine for now. But people may want to “redo” the kitchen later including installing pulls on the drawers. Make sure, then, that you avoid the “corner problem”. There are several ways to successfully turn the corner. The lazy susan is a popular choice. Cabinet manufacturers make a “base corner” sometimes called a blind corner base, or similar (BC, or BCB). This includes a 1" filler that “pushes” one cabinet away so drawer hardware will clear. The corner base has a large “style” (panel) that enables the installer to “slide” the cabinet forward or back so that its hardware also clears. It also allows the designer to adjust a “run” of cabinets for uneven dimensions. You can put a filler piece on one side of two regular base cabinets, to turn the corner, leaving the corner unusable. Of course this is not usually a good idea, but if you are bidding against a competitor who did this, your bid would naturally be higher, all other things being equal. The corner can also be turned by using a square sink corner, or a diagonal sink corner. BASE CABINET 12" to 24 wide

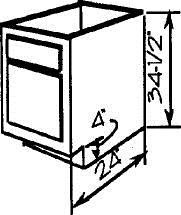

These sizes have a single door and drawer, though some 12" cabinets do not have a drawer. Some manufacturers have a fixed door so you have to specify whether the door is “hinged right” or “hinged left”. But many can be made to open either way (reversible). BASE CABINET 27" to 48" wide These sizes are double drawer and door, though some 27" cabinets may have a single drawer and the double door may not have a “style piece” between the doors. Sometimes the 45" and/or 39" and/or 27" is not available. BASE DRAWER CABINET 12" to 24" wide Most drawer stacks have 4 drawers though some have 3. Bread boards are optional on most base cabinets but it is common to put one in a base drawer unit. The 15", 18" 21" and 24" are most popular though the 21" is not always available, nor is the 12". SINK BASE CABINET 24" wide This is a single door cabinet for a single sink. Often used as a cooktop cabinet and for a range base with some cutting. Some manufacturers have reversible doors, others have to be specified right or left hinging. No drawers and usually no shelf. Differs from a sink front, which is described later SINK FRONT 24" to 30" This is just the front, no sides back or bottom. It is cheaper than a base unit, but by the time other pieces are bought and attached it may be just as expensive (normally a sink base is preferred). You may find it noted SF27-24. Since it’s just a front, the edges can be cut down to alter the size. In this case it comes 27" but can be cut down to a 24" if needed. Many times a 30" is a double door, but not always. SINK FRONT 30" to 48" wide Same notes as the 24" except a double door with false drawer fronts. 36" is most common and not all sizes are available. Some are made so 6" total can be cut off (3" per side). SQUARE SINK FRONT 40" wide Another way to have a corner sink. Needs “L” shaped sink. SINK BASE CABINET 27" to 48" wide A cabinet with no drawers (but with false drawer fronts) to receive a sink which would be set through a hole cut in the counter top. It usually has no shelves. The 36" size is the most popular by far, then 30" and 33". Not all increments are always available. DIAGONAL SINK FRONT 36" to 42" wide Similar to 24" sink front but with “wings” on each side, at 45° to cut diagonally across a corner. Can use a standard sink. A diagonal sink sounds “cute” but any sink in a corner makes that area quite congested. Think twice about using a corner sink. At Paul Cabinet Sourcing, we are proud of custom making base cabinet of any type and size upon customer's needs. Let's have a in depth look at common kitchen cabinets. The figure below shows an overall view of a simple kitchen cabinet layout. Then common cabinet types and sizes follow. A SIMPLE KITCHEN LAYOUT WITH SOFFIT, WALL AND BASE CABINETS BASE CABINETS Base cabinets are approximately the dimensions shown to the left. They may have a full shelf, a half shelf, or pull out shelves or trays, depending on the manufacturer. They usually just have their width as part of the name, because the height is constant at 341/2" (when a 11/2" thick counter top is put on top the cabinet working height is 36"). For example, a B24 means a Base unit 24" wide. Another letter or two can be added to indicate some base cabinet other than a “plain” base cabinet. For example, a DB24 (or BD24) means a Drawer Base (or base drawer) unit 24" wide. An SF36 means a Sink Front 36" wide. Some cabinets may do “double duty”. For example, the same base cabinet may be used for a sink base, or a range base. It could be named RSB30 meaning Range/Sink Base 30" wide. Manufacturers vary in the way they name cabinets. Some put the letters first, others the numbers. Some reverse the letter order, but with the basic knowledge covered in this course you can soon figure out what the names mean. Standard base cabinets come in multiples from 9" to 48". Some manufacturers make longer “starter” assemblies that might contain a sink base, a drawer base and a regular base. Common lengths for these are from 5' to 8' in full foot sizes, but, as always, sizes vary with manufacturer. For Paul Cabinet Sourcing cabinet manufacturing network, the most regular base cabinet size is from 9" to 36". We sometimes do 39" or 42" too but not often and it depends on customer's needs. There are three main ways cabinets are handled. Paul Cabinet Sourcing mainly apply the second and the third. The first is where cabinetmakers custom build the cabinets on the job or in their local shops. They take the actual dimensions, buy sheets of plywood and construct the exact sizes needed for a specific kitchen.

The second is where a manufacturer builds cabinets in a cabinet factory, all to set sizes and specifications. This is quite common with low and medium priced cabinets. They just manufacture their set sizes on standard production runs. A wholesaler or stocking retailer “stocks” a variety of sizes before a sale is made just like many other products in your store. The advantage is they are available immediately (if you have the right sizes and styles in stock). It puts a burden on the designer to pick out and “put together” the pieces needed to exactly fit the kitchen, from the limited choices. Usually the standard base and wall cabinets are made in 3" increments from 9" to 48", but not every 3" increment size is made by all manufacturers. The most common 3" increment not manufactured is probably the 45" wall and 45" base cabinet. Next size omitted from a line up is probably the 39" cabinet. Any cabinet other than the standard base cabinet and the 30" tall wall cabinet is even more restricted in sizes available. Check your cabinet manufacturer catalogue. Even with the size restrictions these cabinet factory made cabinets can fit almost every situation. There are fillers, corner bases that have a large centre panel and therefore can be slid up to 3" or more, to take up the “slack”, face frames that can be “shaved” if necessary, etc. It may take some planning on your part, but these cabinets should be able to work in 99% of the kitchens you have. The third choice, usually with medium and upper priced kitchen cabinets, is where the cabinet manufacturer has set sizes, but does not make them until an order is received. Of course this means a two to ten week, or more delay before receiving the cabinets. An advantage is that the manufacturer will alter the set cabinet size, for an additional charge, so that no filler pieces are needed and the cabinets can fit exactly. They can also stain the exposed cabinet ends that need it and possibly use a more economical wood for the ends that are covered. When you deal with a certain kitchen manufacturer you don’t get a choice of methods. Each manufacturer works with its method. One of the big advantage our customer gain when work with Paul Cabinet Sourcing is, our selected Chinese cabinet manufacturers formed a cabinet manufacturing network, which enable us always choose the best cabinet manufacturing methods to cater to customer's particular needs. There are many cabinet types and accessories. Since there are a great many cabinet manufacturers and individuals who build cabinets it is impossible to be 100% accurate in every description of sizes, styles, types of hardware, etc., that are available.

You can learn a lot from this information but nothing will beat using information specific to the cabinets you sell. You should have your main suppliers’ catalogue with you right now. When this text shows base cabinets, for example, study it. Then refer to your cabinet supplier catalogue to see what cabinet sizes they have. Look also for the accessories available with your brand. Paul Cabinet Sourcing mainly focus on American standard kitchen cabinet, but also do European style cabinets. Some kitchen cabinet types include base cabinets, wall cabinets, tall cabinets and more. Some “sub” types of these include corner cabinets, sink bases, sink fronts, range bases, range fronts, drawer bases, vertical partition bases, lazy susans, peninsula and island cabinets, microwave cabinets, oven cabinets, utility cabinets, pantry cabinets and more. Some common accessories include cutlery dividers, bread and flower boxes, valances, spice and wine racks, knick-knack and other open shelves, bread and cutting boards, pull out shelves, baskets, pan and lid racks, end panels both finished and unfinished, dishwasher front panels, plate railing, cove, prefinished panelling to match and more. For bathroom cabinets there are vanity bases, vanity sink bases, vanity sink fronts, vanities with drawers, medicine cabinets and more. You get the idea!  White Shaker Cabinets White Shaker Cabinets Knowledge of kitchen centres and kitchen theory will enable you to design a better kitchen with cabinets supplied by Paul Cabinet Sourcing. Basically you put the refrigerator on or near one end of the cabinets, the sink in the middle and the range on the other side of the sink. Then you put in the maximum reasonable amount of base and wall cabinets using the kitchen layout shape that best fits the situation. To be a little more sophisticated make sure you have at least the minimum countertop space on each side of the appliances. Then check the distances between appliances and the overall work triangle length. To be really successful in kitchen sales you need to be an expert. Your customers can tell whether you have just minimal knowledge or whether you are well informed. If you are an "expert" in kitchen design and layout, your customers will have the confidence in you to spend the large amount of money at your store, which goes along with a kitchen sale. You get to be an expert by asking questions, reading other kitchen design information, attending schools put on by the manufacturers, installing some cabinets, learning how to sketch kitchens, learning more about the benefits of your cabinet line from Paul Cabinet Sourcing, learning to estimate and price cabinets accurately and, of course, learning and using good selling tools. This is the last post about kitchen design. From next post, we will share with you something about kitchen cabinet manufacturing. Feel free to contact Paul Cabinet Sourcing if you have a question about American style cabinet manufacturing in China. Sometimes you have little to say about this but it pays to bring it to your customers' attention.

They may have not given it much thought, concerning themselves mostly with the layout of the new kitchen and the desired cabinet style and colour. Remodelling time, however, is the time to consider changing or adding windows and/or adding lighting and electrical outlets. Many older homes do not have adequate ventilation to exhaust cooking odours as well as excess moisture. Now would be the time to consider fixing that situation. Natural lighting is preferred by many people. This could mean more and/or bigger windows. Also general lighting, usually a ceiling fixture, is common. Then each work centre and appliance, as appropriate, should have its own direct light. Nobody ever complains about his or her kitchen having too much light, but a lot of kitchens are grossly underlit. If a home has an adequately sized electrical entrance there is usually room to add several electrical circuits. If the kitchen needs them it is usually affordable to simply add a circuit or two. If the home needs a new entrance (fuse or circuit breaker box) it's a sizable, but usually worthwhile investment. Lack of proper ventilation can have the short term effect of undesired cooking odours floating all through the house. And the long term effect of creating serious moisture problems that will cost a lot of money in a few years. The most common location for an exhaust fan is over the range. Some kitchens have a wall mounted fan that draws general air out of the kitchen. The most effective ventilation exhausts the stale air and moisture to the outside. A compromise is the filtered vents that return the air to the room. These are not a good choice because they do nothing about the moisture problem. But they may help the odour problem. Do your best to help the customer see the value of “doing things right”. It may cost them a little more but they will reap the benefits for years and years and they’ll be happier. This is the same concept that Paul Cabinet Sourcing hold to help our customers establish and manage their cabinet line from China.  KITCHEN PLANNING GUIDELINES 1. When using an existing refrigerator be sure to consider the door swing in planning its location. (Some refrigerator doors can be reversed.) 2. Since the refrigerator and built-in oven are tall, place them so they do not block the flow of work from one counter to another (generally you place them at the end of a line of cabinets). 3. If reasonable, place the refrigerator nearest the entrance. 4. Avoid placing the refrigerator right next to a wall that extends past the refrigerator. The doors will open but you may not be able to remove the shelves or vegetable crispers. 5. Keep a range or surface unit at least 9" or more away from a window curtain to avoid possible fire hazard. 6. Plan your layout so that as foods are prepared they move toward the dining area. 7. Locate the range to the right of the sink for right handers, to the left for lefties. 8. A sink under a window is preferred by many. 9. Plan a 24" cabinet next to the sink if no dishwasher is included at this time. Then one can be added later with a minimum of redesign. (But don’t plan a drawer base in this space. You won’t want to remove that). 10. A medium sized house should have a minimum of 10' of wall cabinets and 10' of base cabinets. 11. Plan at least one base drawer cabinet. 12. Understand and avoid the “corner” problem of drawer clashing. (More on that later in this chapter). 13. Keep cabinets at least 2" away from door and window trim so you have “someplace to go” if measurements are off a little. Also when the trim is not “plumb” it is not so evident with a wider gap such as 2 or 3 inches. 14. Bread boards and/or chopping blocks are popular. 15. To make a room seem larger use light colors on all surfaces. 16. A kitchen floor is often lighter than other floors in the house. 17. A lot of sunlight in a kitchen is desired. There are several minor centers. Some homes have only the mixing centre, some have two or more and some have them all.

MIXING CENTRE Here is 36" or more of uninterrupted counter space for preparing breads, pies, cakes, cookies and much more. You would design storage for mixers, blenders, etc., since this is the point of first use for many items. PLANNING CENTRE A desk height (30") counter with knee space where a person can sit down to do meal planning, answer the phone, take messages is a nice addition if you have the space. It is usually located outside the work triangle at a quiet end of the kitchen. Paul Cabinet Sourcing's advice is Planning centres may be expanded to include a computer for meal planning, personal finances, homework, etc. A planning centre also may be the control point of your audio, video and security systems. So you see, what starts out as an “extra” centre in kitchen planning can turn out to be a critical part of a lifestyle. If you are well informed in these areas, give your customers good ideas and help them make decisions they will be happy with today and tomorrow, you’ll have a good chance to get their repeat business, as Paul Cabinet Sourcing always believed. EATING/DINING CENTRE Many people prefer to eat most meals in the kitchen area rather than a formal dining room. This eating centre can be as a part of the regular countertop, often as part of a peninsula. It may mean keeping the regular countertop width of 25" to 26" and just putting stools by the counter. Often though, the countertop is made an extra 8" to 18" wider so there is knee space under the extra countertop overhang. Often the overhang is lowered to chair height, as many people prefer sitting on chairs instead of stools. Some kitchens provide space for a regular table and chairs. The “L” shape works well for this preference, though just off the end of a corridor kitchen works also, as can any kitchen shape if there is enough room. Another choice is to provide a built-in table and bench seats in what is commonly called a breakfast or dining nook. Allow 36" space in all directions for each person, when designing these areas. LAUNDRY CENTRE A clothes washer and dryer are the common appliances in this area. Depending on location and preferences, it may also include a laundry sink, storage cabinets, hamper, a clothes folding table. Possibly a built-in ironing board or space for a free standing one and maybe even a sewing area. MAJOR KITCHEN CENTRES FOOD STORAGE FOOD PREPARATION CLEAN-UP MINOR KITCHEN CENTRES MIXING PLANNING EATING/DINING LAUNDRY All kitchens should have a “minor” centre called the mixing centre. This is nothing more than 36" to 42", or more, of uninterrupted counter space. Some kitchens also contain these “minor” centres (and some have even more): a planning centre, a laundry centre, or an eating centre. All the centres can have “remote” locations as well. For example, the food storage centre revolves around the refrigerator and includes kitchen cabinets near the refrigerator used to store food. But a pantry cabinet is also part of this centre yet may be located some distance away. A freezer is part of this centre, if the family has one, but can be located a good distance away from the refrigerator, or it may be a part of the refrigerator. It can also be located in the basement, garage, or other locations. The counter space within the various centres often overlap. The same 24" next to the refrigerator, which is used to set groceries down on, may be part of the minimum 36" of uninterrupted counter space needed for the mix centre. The point is this: this kitchen design blog information covers common situations, but there are a lot of different situations that occur. So use your imagination and good judgement as you review the illustrations and examples.  THE FOOD STORAGE CENTRE The refrigerator is the main appliance in this centre. A freezer is also a popular appliance though its location varies widely as previously noted. This centre is often located conveniently near the back or side door so groceries can be brought in and set down next to the refrigerator on a 15" to 24", or wider, countertop. Wall and base cabinets around the refrigerator will be used to store food. A pantry cabinet or a closet used for storing canned goods is often a nice design touch. And food is also stored throughout the kitchen depending on the family’s lifestyle and preferences. Your customer may want a flour bin and/or bread box built into a cabinet. Or any of the many other accessories offered by your favourite cabinet supplier. FOOD PREPARATION CENTRE - INCLUDING COOKING Preparation of food can mean washing and cleaning vegetables, opening microwavable packages, baking, boiling, frying, etc. This means the main appliance will be the range, but will also include the sink, a microwave and any other small appliances used in food preparation. A list of these would include a crock pot, toaster, blender, electric fry pan, popcorn maker and more. Some kitchens will include a cooktop and then a separate oven, or two. A grill type range is a possibility as well as a second microwave. Who knows what new appliances will be commonplace in the next 5 to 20 years. Kitchens designed in the past did not plan for microwaves. You’ll need enough counter space on one or both sides of the major cooking appliances. You’ll want base and wall cabinet storage for pots, pans, cooking utensils, seasonings, measuring devices, the smaller appliances and more. You may want a spice rack, a bread board, a cutting board, or any of a number of “extras” that are available, in this food preparation area. A general rule is to store items at point of first use. So pots might be kept near the sink but frying pans near the range, for example. The food preparation area requires careful individual design considerations because of the wide range of preferences individuals have. Ask your customers lots of questions to determine their kitchen habits and how best to design their kitchen so it meets their needs. CLEAN-UP CENTRE The sink is the main item, but a dishwasher is also very popular. If the customer does not have or want a dishwasher right away, design a 24" base cabinet to the right of the sink (for right handers) so it can be taken out later and a 24" (standard size) dishwasher can be added. A sink is used in all phases of kitchen work, so it should be located between the range and refrigerator for convenience. Some kitchens will have two sinks, so that could affect placement. Remember that that counter space is needed on both sides of the sink. For stacking dirty dishes and then for stacking clean ones. Some designers will say a single bowl sink is adequate if you have a dishwasher, but most people end up wishing they had a double bowl sink, so try to avoid the single bowl in your designs. A waste disposal is fairly common and a trash compactor might also be desired. The cabinets in this area should include space, probably under the sink, for detergents and cleaning supplies. They might also include a broom closet nearby as well as drawers for dishcloths and towels. A lot of people prefer to store their “everyday” dishes and silverware in nearby cabinets also. These are the three major kitchen centers. |

Archives

February 2023

Categories |

RSS Feed

RSS Feed